Metallurgy Laboratory

Our output quality apart from our own Machining and Grinding processes, largely depends upon the Input Quality in the form of Forged Shafts/Material received from the forger. All the efforts that we may try and ensure in machining processes would be futile if the Raw material or Input Quality is not up to the mark. Apart from ensuring receipt of authentic Material Test Reports from the forger, we at Srinivas harbours mini-metallurgy lab to inspect forgings and other child parts like Pin, Key, Gear and Phonic Wheel kind of crankshaft assembly.

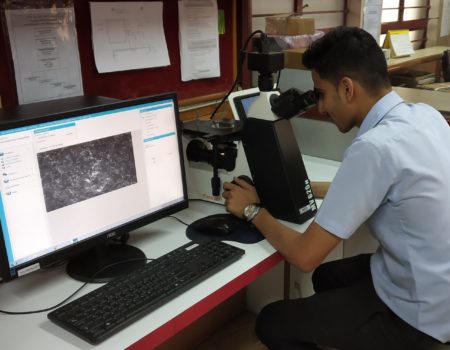

The strategy is in place for erecting a quintessential facility which can assure the prospective collaborator about quality assurance and control. It has been our prudent efforts in garnering the expertise w.r.t. metallurgy over last few years, as otherwise the domain remains a grey area in our endeavour of achieving excellence. Our Metallurgy Lab is equipped with Surface Hardness Testers, Inverted Microscope for Grain Structure analysis and Charts of comparison along with repository of data & destructive samples pertaining to preceding years. The lab and its functioning are duly supported by External Metallurgist on consultation basis and our own dedicated Engineer having a watchful eye.